Used Auto Leveling Sensor (ALS) WaferImprove equipment setup time

Used Auto Leveling Sensor (ALS) WaferImprove equipment setup time

Enhance process uniformity with objective and reproducible level adjustments

Reduce equipment maintenance time with wireless measurement

Reduce particles and increase yield with improved equipment set-up

Wafer-shaped: Available in 200mm and 300mm wafer sizes

Highly accurate: Measures horizontal leveling

Wireless: Transmits data wirelessly to your laptop or PC in real-time

Data logging: Records raw data in CSV format for analysis

Used Auto Vibration Sensor (AVS) WaferSpeed equipment qualification with wireless vibration measurements

Used Auto Vibration Sensor (AVS) WaferSpeed equipment qualification with wireless vibration measurements

Shorten equipment maintenance cycles with a wafer-like accelerometer

Lower equipment expenses with objective and reproducible data

Optimize equipment productivity and yield by maximizing acceleration and minimizing vibration

Wafer-shaped: Available in 200mm and 300mm wafer sizes

Highly accurate: Measures acceleration in three directions. x, y and z. with a range of +/-2G, resolution of +/-0.01G and frequency response 0 to 200 Hz, -3dB

Wireless: Transmits data to your laptop or PC in real-time (CSV raw data also available)

Easy-to-use software: CyberSpectrum software provides the user with real-time visual feedback and can record and replay logged data for review and analysis

Used Auto Teach System (ATS) Camera WaferAccurate wafer handoff calibration improves yield and lowers particulate contamination.

Used Auto Teach System (ATS) Camera WaferAccurate wafer handoff calibration improves yield and lowers particulate contamination.

WaferSense ATS wafer moves through your semiconductor equipment just as a wafer to capture offset data for accurate

calibration of transfer positions.

Wireless communications and wafer form factors reduce equipment downtime from hours to minutes.

Wireless and vacuum compatible, the ATS teaching wafer makes calibration safe for both technicians and

process stations.

Visual inspection speeds up troubleshooting and lowers consumable expenses.

ATS displays real-time images to technicians as robots move ATS through the tool.

Used Auto Gapping System (AGS) WaferImprove uniformity and yield with wireless gap measurement wafer

Used Auto Gapping System (AGS) WaferImprove uniformity and yield with wireless gap measurement wafer

Achieve chamber matching and parallelism in a very short timeMeasures gaps at three points or five points to allow you to achieve the ideal leveling and platen/showerhead parallelism for your CVD equipment Objective and reproducible gap adjustments result in better tool-to-tool process uniformity

Take the human variable out of adjusting your equipment with objective (numerical) measurements. Numerical and graphical

displays make adjustments fast and simple.CyberSpectrum software, the graphical user interface provided with AGS, displays numerical and graphical measurements in either

millimeters or inches from inside the process chamber under a vacuum, letting you see the effect of your adjustments in real-time.

Wireless technology eliminates broken wires and vacuum leaks.

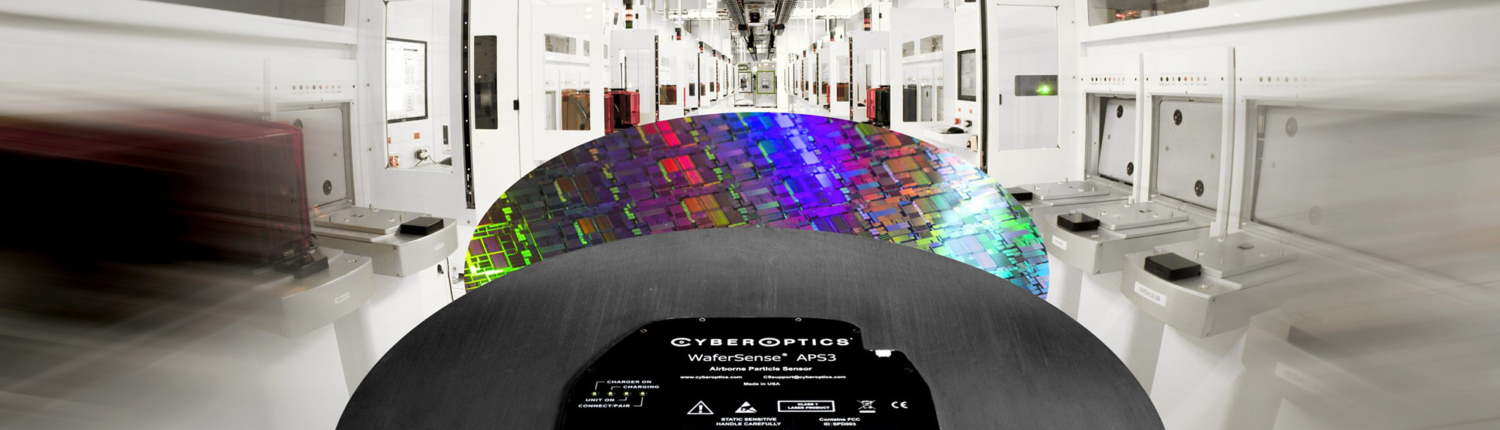

Used Airborne Particle Sensor (APS) WaferDetect particles in real-time without opening the tool, so you don’t need to expose process areas to the environment. The APS wafer is used for rapid tool partitioning and segmentation.

Used Airborne Particle Sensor (APS) WaferDetect particles in real-time without opening the tool, so you don’t need to expose process areas to the environment. The APS wafer is used for rapid tool partitioning and segmentation.Reports particles in 0.14μm and 0.5μm bin sizes and larger particles in 2, 5, 10 and 30 μm bin sizes.

Available in 150mm, 200mm, and 300mm wafer sizes.

Transmits particle data to your laptop or PC in real-time.

CyberSpectrum application software provides the user with real-time visual feedback and can record and replay logged data for review and analysis.

Raw data also saved in CSV format for analysis.