Ultraviolet curing (commonly known as UV curing) is a photochemical process in which high-intensity ultraviolet light is used to instantly cure or “dry” inks, coatings or adhesives. Offering many advantages over traditional drying methods., UV curing has been shown to increase production speed, reduce reject rates, improve scratch and solvent resistance, and facilitate superior bonding.

UV Curing Benefits:

- UV curing systems take up less space, so shops can utilize more revenue-producing equipment

- UV uses less energy, therefore significantly cutting operating costs

- UV ink goes farther than solvent-based ink (up to 60 percent per gallon)

- UV curing can increase throughput four times compared to solvent-based processes

- Nearly eliminates clean-up time, adding to the time available for production

- UV technology does not pollute, inside or outside the shop

In addition to printing benefits, UV curing is also used to instantly solidify coatings, inks, and adhesives with a cool, clean beam of light. Volatile Organic Compounds (VOC) found in the noxious, flammable solvents used by conventional coatings, adhesives and inks are completely eliminated. The ultraviolet curing process is a photochemical reaction where free flowing molecules, excited by UV radiation, link to form solid polymer chains. Small amounts of chemicals known as “Photoinitiators” act as catalysts, allowing the UV-curable adhesives and coatings to remain liquid, then instantly solidify or “cure” the material after a few seconds of exposure to Ultraviolet (UV) light.

UV-LED Spot Curing System4 independent UV irradiation channels

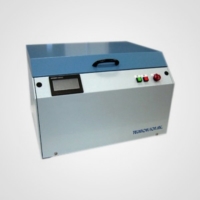

UV-LED Spot Curing System4 independent UV irradiation channels UV Curing System, Model UVC-408Equipped with a 1KW high-pressure mercury lamp

UV Curing System, Model UVC-408Equipped with a 1KW high-pressure mercury lamp UV Curing System, Model UVC-512Equipped with a 2 KW high-pressure mercury UV light source

UV Curing System, Model UVC-512Equipped with a 2 KW high-pressure mercury UV light source UV-LED Curing System Model UVC-200Applicable for all UV films with 365nm wavelength

UV-LED Curing System Model UVC-200Applicable for all UV films with 365nm wavelength UV-LED Curing System, Model UVC-300Applicable for all UV films with 365nm wavelength

UV-LED Curing System, Model UVC-300Applicable for all UV films with 365nm wavelength Automated UV-LED Curing System, Model UVC-300AApplicable for all UV films with 365nm wavelength

Automated UV-LED Curing System, Model UVC-300AApplicable for all UV films with 365nm wavelength