UV-Ozone Cleaning Applications

- Cleaning Silicon and Silicon Nitride AFM/SPM Probes

- Ultraviolet Curing of UV-adhesives

- UV photo-patterning of SAM surfaces

- Cleaning Surface Plasmon Resonance (SPR) chips

- Cleaning Quartz Crystal Microbalance (QCM) sensors

- Wafer Cleaning

- Surface Disinfection and Cleaning

- Surface Activation

- Cleaning Silicon and Silicon Nitride AFM/SPM Probes

- Ultraviolet Curing of UV-adhesives

- UV photo-patterning of SAM surfaces

- Cleaning Surface Plasmon Resonance (SPR) chips

- Cleaning Quartz Crystal Microbalance (QCM) sensors

- Wafer Cleaning

- Surface Disinfection and Cleaning

- Surface Activation

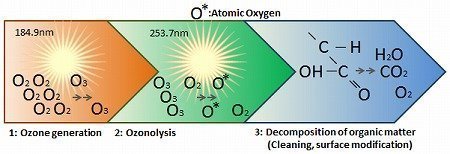

Why UV Ozone Cleaning Process?

While there are several options for surface cleaning and sample preparation methods, UV-ozone cleaning shows several advantages over other methods.

- Improved wettability resulting in better bonding and coating adhesion

- Does not damage materials

- Simple, fast and cost effective method of cleaning

- Does not induce electrostatic charge on samples

- Low Charging Damage on Substrates – In case of plasma treatment, charging damage caused by ion bombardment can be a serious challenge. It leads to degradation of electrical characteristics of devices. UV-ozone treatment offers surface treatment using oxygen radicals without plasma discharge.

- No Hazardous Effluent – Wet cleaning requires effluent disposal of chemicals. In contrast to the wet cleaning method, UV-ozone treatment is a completely dry and chemical-free process.